In 2012 I was invited to Philips Ledalite, in British Columbia, Canada, to work on a special project.

Led by Matthew Kennedy, we were given priority status among the projects, which meant that we could use the goniometer and put our prototypes inline with the manufacturing to have the quickest turnaround.

Led by Matthew Kennedy, we were given priority status among the projects, which meant that we could use the goniometer and put our prototypes inline with the manufacturing to have the quickest turnaround.

What started as one of the providers, supplying a single type of fixture, grew to the main provider supplying majority of fixtures.

The importance of light in the workplace cannot be understated. Even though Apple campus features superb panoramic windows and lightwells, it is still important to provide controlled, tuned and glare-free lighting for optimal work.

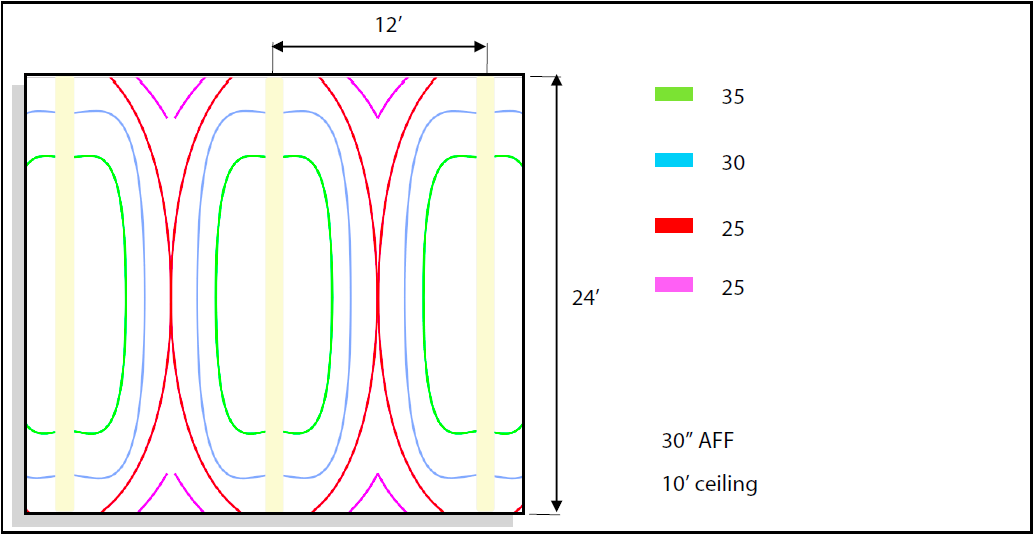

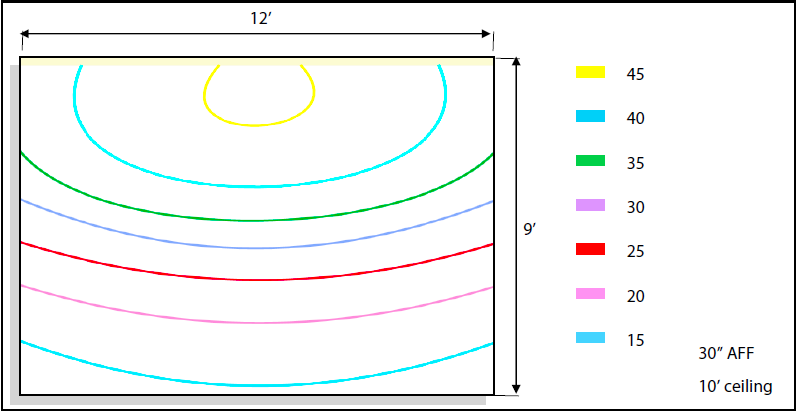

The Ribbon light is inset into the white porcelain-like concrete ceiling that diffuses the light. We have done a lot of R&D, and tests to have the light source continuous, and even (no hot spots, no shadows) and at the same time provide batwing lighting for optimal even illumination at desk height. The ribbon can be a couple of dozen feet long without any visible seams, it was also thought through on installation to have built-in safety features and modularity.

The crown jewel of our lighting proposal was the Cove lighting features on the perimeters of the building as well as a slightly different configuration inside the offices.

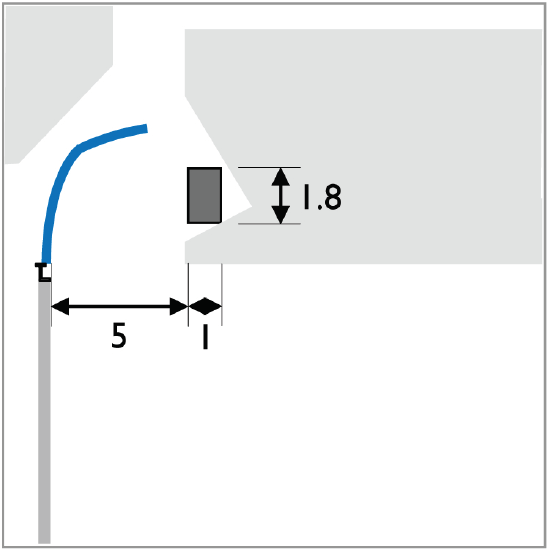

The sections on the perimeter, hugging the glass wall, are thought through carefully as that is also how Norman Foster Architects designed passive ventilation.

Corian was chosen as the reflective material in order to match with the bone white concrete, as well as for its property to be thermoformable and lastly to be able to make it seamless - as Corian is prized for seamless repairs and joints.

In addition, the LEDs had to be tucked in a way not to be seen from any angle and only the illuminated Corian, with a specific geometry, cast a diffused warm light.

In addition, the LEDs had to be tucked in a way not to be seen from any angle and only the illuminated Corian, with a specific geometry, cast a diffused warm light.

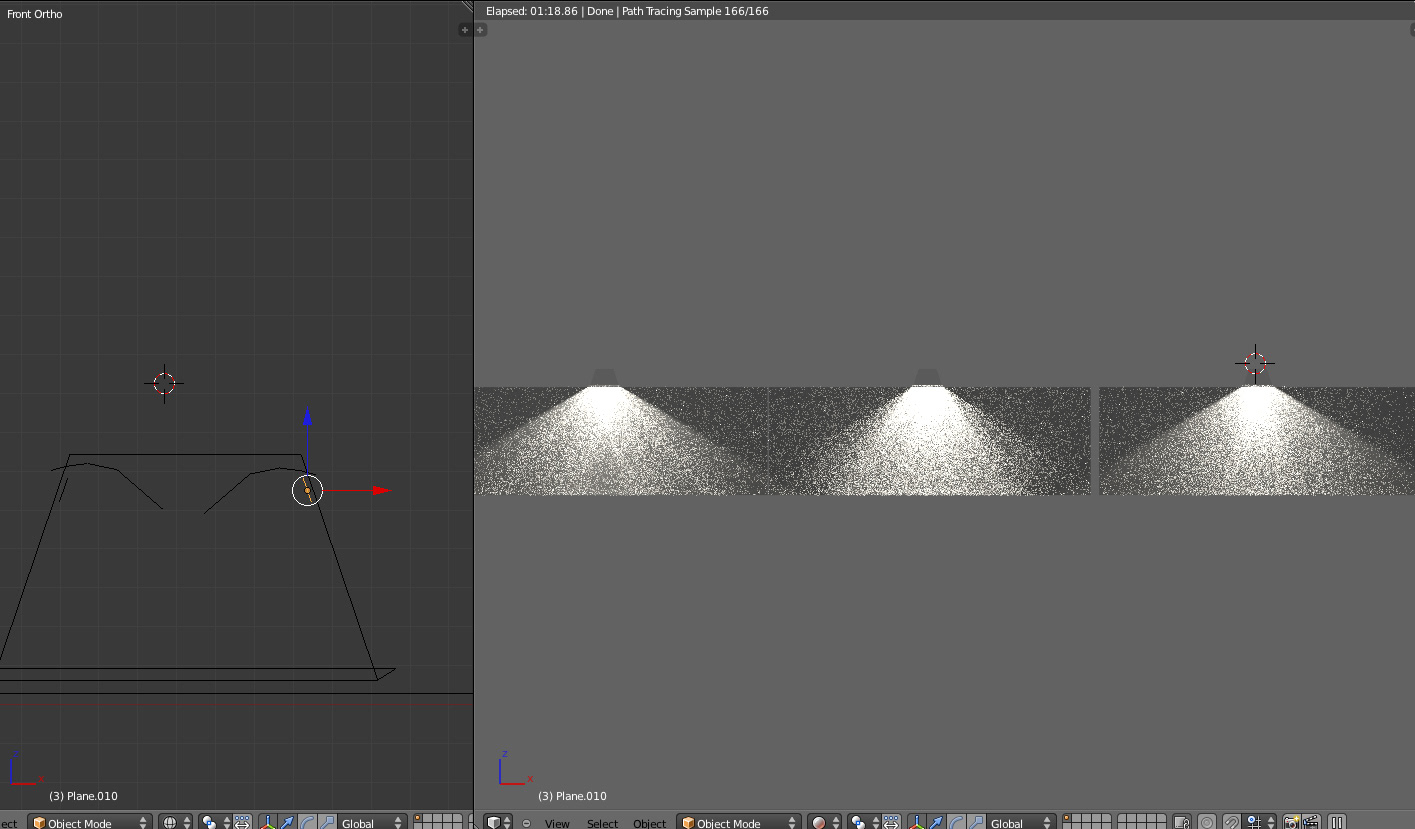

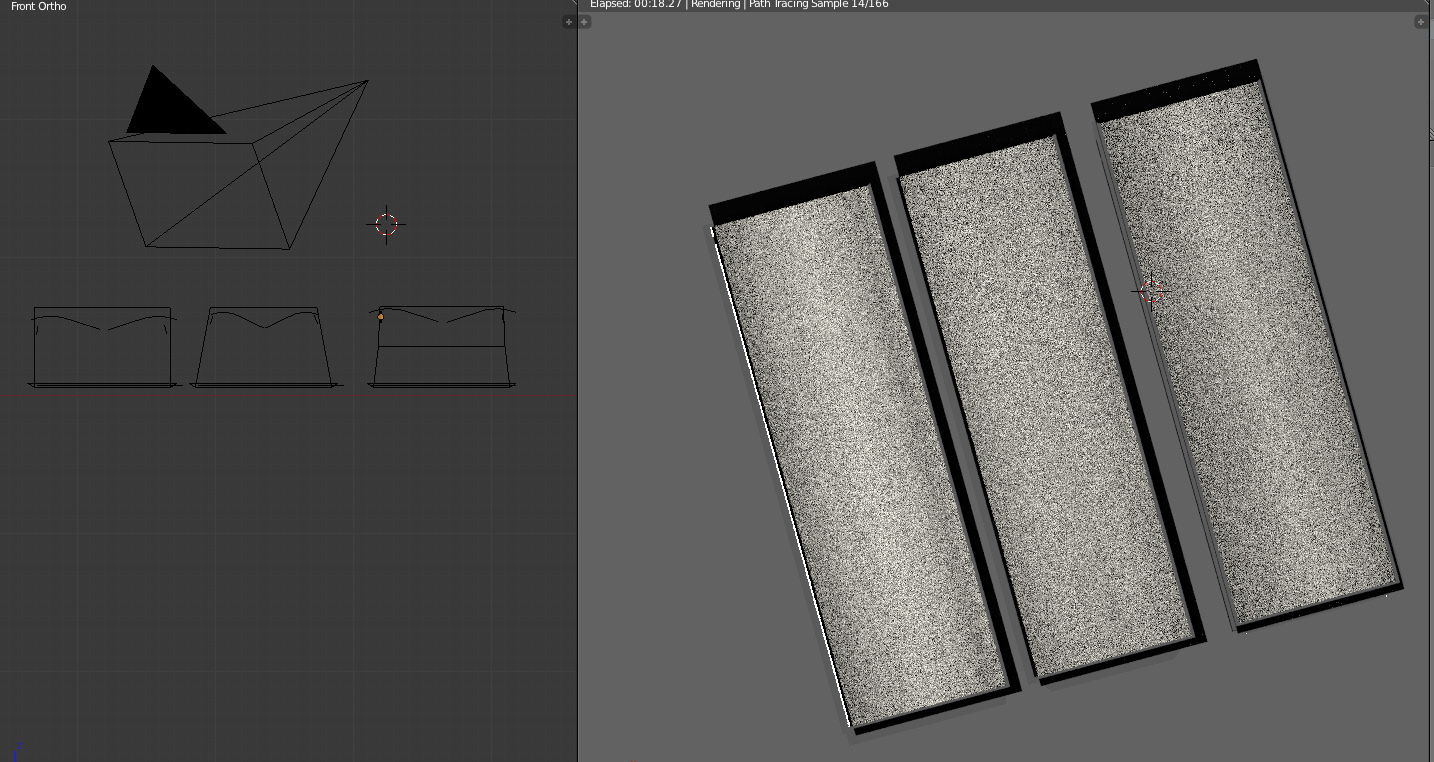

While we had access to the goniometer to evaluate prototypes, I tried to leverage computer aided simulation to speed up the process and run through several ideas before building them. Using blender and Lux render (unbiased physically based rendering engine) I was able to simulate not only how the light is cast, a goniometric diagram of sorts, but also how the hotspots form on the emitting surface.